Na'urar Tambarin Tambari Mai Daidaito Nau'in Bugawa 40T

Bayanin Samfurin

Wani abin lura na wannan na'urar buga takardu shine tasirinta mai yawa da juriyar lalacewa. An zaɓi kayan jagorar da aka yi amfani da su wajen gina ta musamman don jure amfani mai yawa da kuma samar da kwanciyar hankali na dogon lokaci. Wannan yana nufin za ku iya tsammanin daidaiton na'urar buga takardu ɗinku zai kasance daidai tsawon lokaci, wanda ke rage buƙatar gyare-gyare akai-akai da kulawa. Tare da wannan ci gaba mai dorewa, za ku iya mai da hankali kan haɓaka samarwa maimakon damuwa game da lalacewa da tsagewa a kan na'urar ku.

Baya ga kyakkyawan aiki, Knuckle High Speed Precision Press yana da ƙira mai kyau da ergonomic. Kwamitin sarrafawa mai sauƙin fahimta yana ba da damar aiki da daidaitawa cikin sauƙi, yana tabbatar da ƙwarewar mai amfani ba tare da wata matsala ba. Hakanan an sanye shi da kayan aikin tsaro na zamani, gami da maɓallin dakatarwa na gaggawa da murfin kariya don tabbatar da lafiyar mai aiki da hana haɗurra.

Babban Sigogi na Fasaha:

| Samfuri | MARX-40T | ||||

| Ƙarfin aiki | KN | 400 | |||

| Tsawon bugun jini | MM | 16 | 20 | 25 | 30 |

| Matsakaicin SPM | SPM | 1000 | 900 | 850 | 800 |

| Mafi ƙarancin SPM | SPM | 180 | 180 | 180 | 180 |

| Tsawon mutu | MM | 190-240 | |||

| Daidaita tsayin mutu | MM | 50 | |||

| Yankin zamiya | MM | 750x340 | |||

| Yankin Bolster | MM | 750x500 | |||

| Buɗewar gado | MM | 560x120 | |||

| Buɗewar Bolster | MM | 500x100 | |||

| Babban injin | KW | 15x4P | |||

| Daidaito | Matsayi na musamman na JIS/JIS | ||||

| Nauyin Matsakaici na Sama | KG | MAX 105/105 | |||

| Jimlar Nauyi | TON | 8 | |||

Babban fasali:

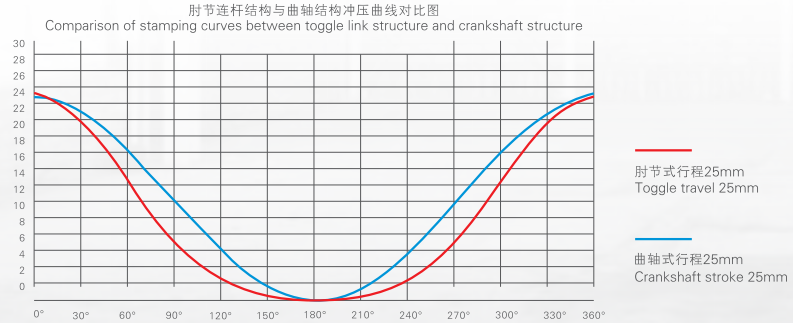

1. Na'urar buga ƙugiya tana ƙara girman halayenta na aikinta. Tana da halaye masu ƙarfi, daidaito mai kyau da kuma daidaitaccen zafi mai kyau.

2. An sanye shi da daidaiton daidaitawa, rage gudun matsewar tsayin matsewa saboda canjin saurin matsewa, da kuma rage matsakaicin matsewar matsewar farko da tambarin tambari na biyu.

3. Tsarin daidaitawa da aka yi amfani da shi don daidaita ƙarfin kowane gefe, tsarinsa yana da allura mai gefe takwas da ke jagorantar shi, yana ƙara inganta ƙarfin ɗaukar nauyin zamiya.

4. Sabuwar birki mai kama da baya wanda ba shi da baya tare da tsawon rai da ƙarancin hayaniya, yana samun ƙarin aiki mai natsuwa. Girman abin ƙarfafawa shine 1100mm (tan 60) da 1500mm (tan 80), wanda shine mafi faɗi ga tan ɗinsu a cikin cikakken samfuranmu.

5. Tare da aikin daidaita tsayin servo die, da kuma aikin ƙwaƙwalwar tsawo, rage lokacin canza mold da inganta ingantaccen samarwa.

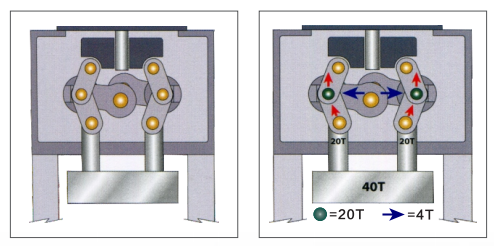

Cikakken Tasirin Tambari:

Tsarin haɗin maɓalli mai daidaitawa a kwance yana tabbatar da cewa maɓalli yana tafiya cikin sauƙi kusa da tsakiyar ƙasan da ya mutu kuma ya sami cikakkiyar sakamako na maɓalli, wanda ya cika buƙatun maɓalli na firam ɗin gubar da sauran kayayyaki. A halin yanzu, yanayin motsi na maɓalli yana rage tasirin da ke kan maɓalli a lokacin maɓalli mai sauri kuma yana tsawaita sabis na maɓalli.rayuwa.

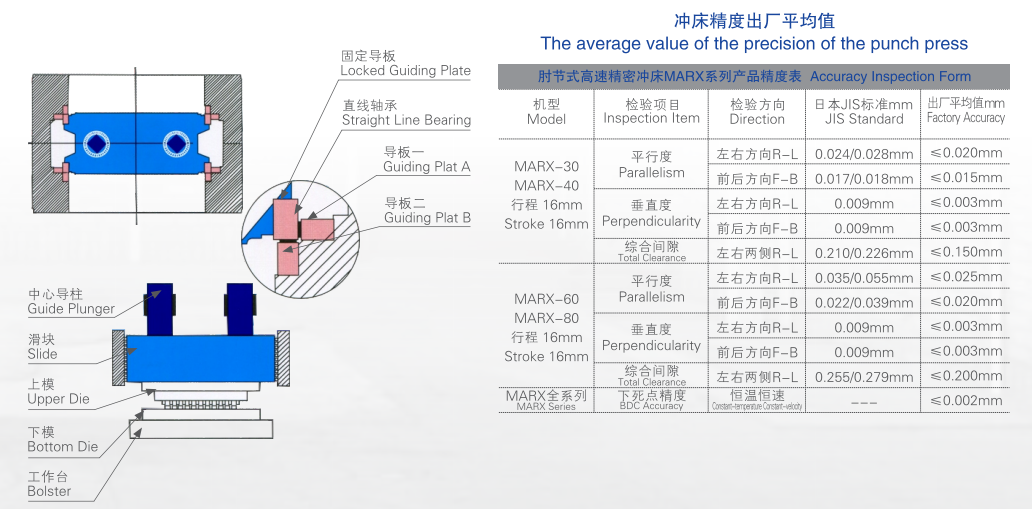

MRAX Superfine Precision yana cikin Kyakkyawan Rigidity da Babban Daidaito:

Ana shiryar da na'urar zamiya ta hanyar jagorar na'urar ninkaya biyu da kuma na'urar jujjuyawar octahedral mai faɗi ba tare da wani sarari ba. lt yana da kyakkyawan tauri, ƙarfin juriyar lodi mai ƙarfi, da kuma daidaiton latsawa mai ƙarfi. Babban ƙarfin juriya da juriya ga lalacewa na

Nau'in Gaɓar Gaɓa Babban Sauri Daidaito Dannawa

Kayan jagora suna tabbatar da daidaiton injin latsawa na dogon lokaci kuma suna tsawaita tazara na gyaran mold.

Tsarin Zane

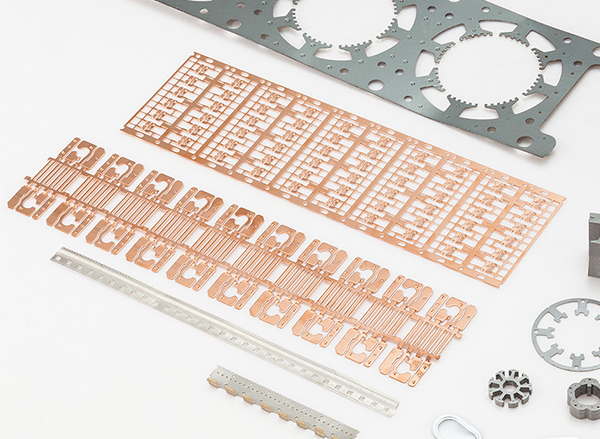

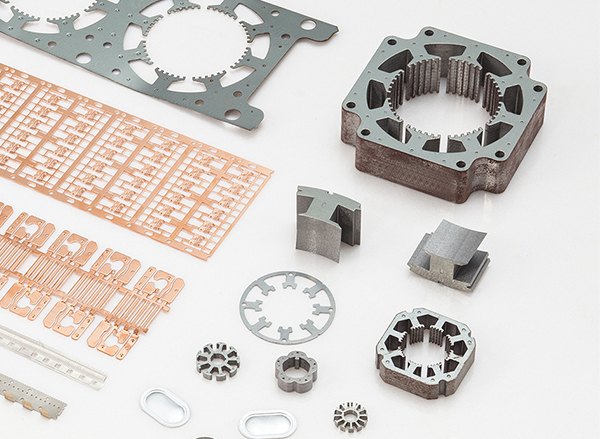

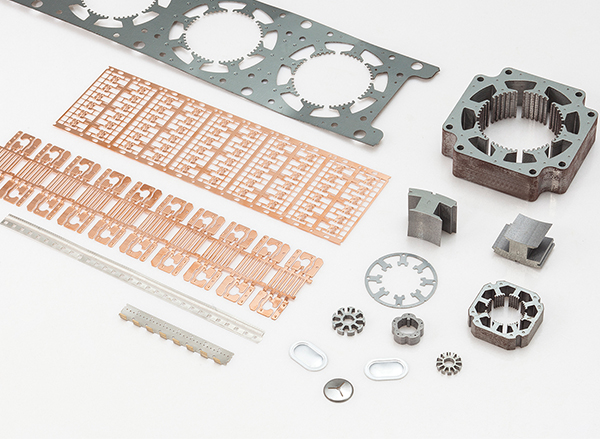

Kayayyakin 'Yan Jarida

Tsarin jagora

Ana manne mashin ɗin da ke cikin kunshin a kan firam ɗin jagora, sannan a haɗa wayoyi masu ɗaure mashin ɗin zuwa ga firam ɗin jagora. A mataki na ƙarshe na aikin ƙera, ana ƙera firam ɗin jagora a cikin akwati na filastik, kuma a wajen firam ɗin jagora ana yanke shi, yana raba dukkan firam ɗin jagora.

Ana ƙera firam ɗin gubar ta hanyar cire kayan daga farantin lebur na tagulla ko ƙarfe mai kauri. Hanyoyi biyu da ake amfani da su don wannan sune sassaka (wanda ya dace da yawan gubar), ko kuma buga tambari (wanda ya dace da ƙarancin yawan gubar). Tambari (huda ko matsewa) ita ce hanya mafi inganci, daidai kuma mai inganci don samar da Firam ɗin gubar a zamanin yau.

Babban dalilin da ya haifar da raunin da aikin gona ya haifar sakamakon injin buga takardu mai saurin gudu na tan 60 na Knuckle shine rashin kayan kariya da kayan aiki masu mahimmanci, da kuma rashin ingantaccen kariya ga ma'aikata don hanyoyin aiki masu haɗari. Dalilin fasaha na haɗarin raunin da injin buga takardu ke yi shine rashin daidaito tsakanin aikin mai aiki da kuma aikin injin.